The Unigrà Method

A tailored approach for your business.

Unigrà industrial products boast the safety and precision of a standardized method based on a tailor-made approach. In fact, each of our products is customized to the specific needs of clients and partners:

We create projects suitable for various applications and processes, actively collaborating with client sand their structures.

We align with European centers of excellence on contaminants to ensure high standards.

Supply chain and transportation are carefully controlled and the refinery and transformation represent the heart of the company.

We continuously define and verify the performance of products to maintain high-quality standards.

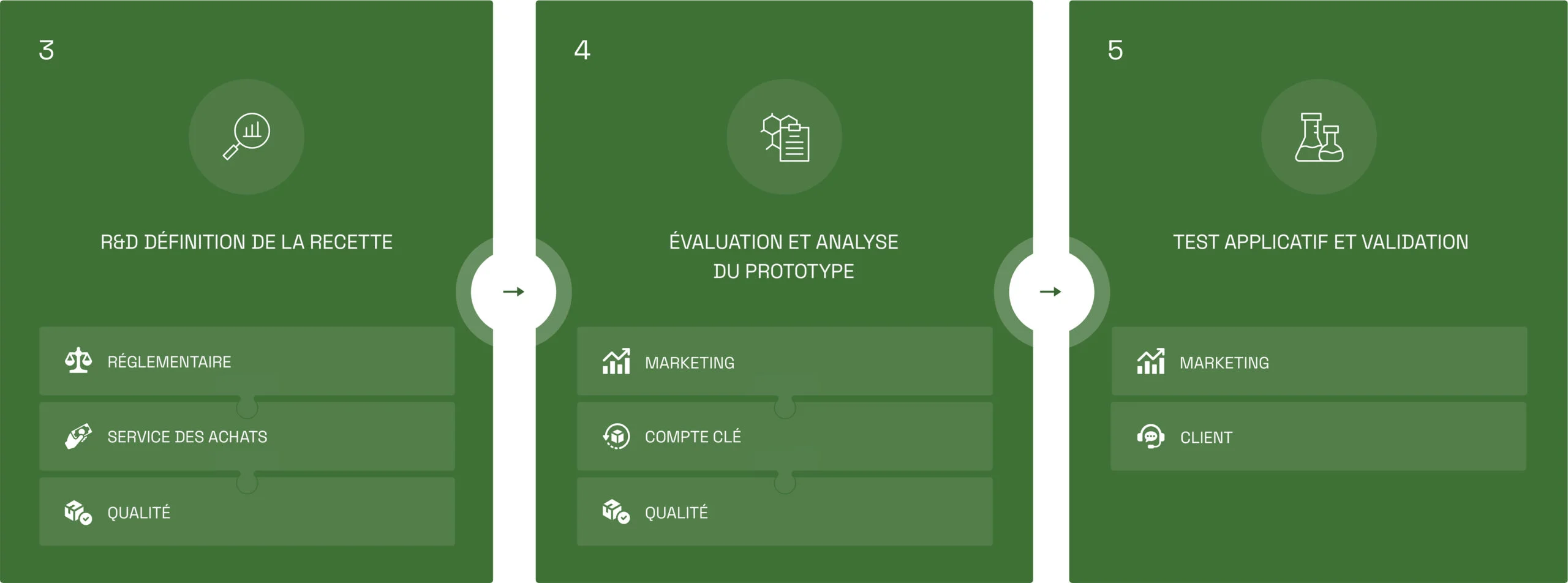

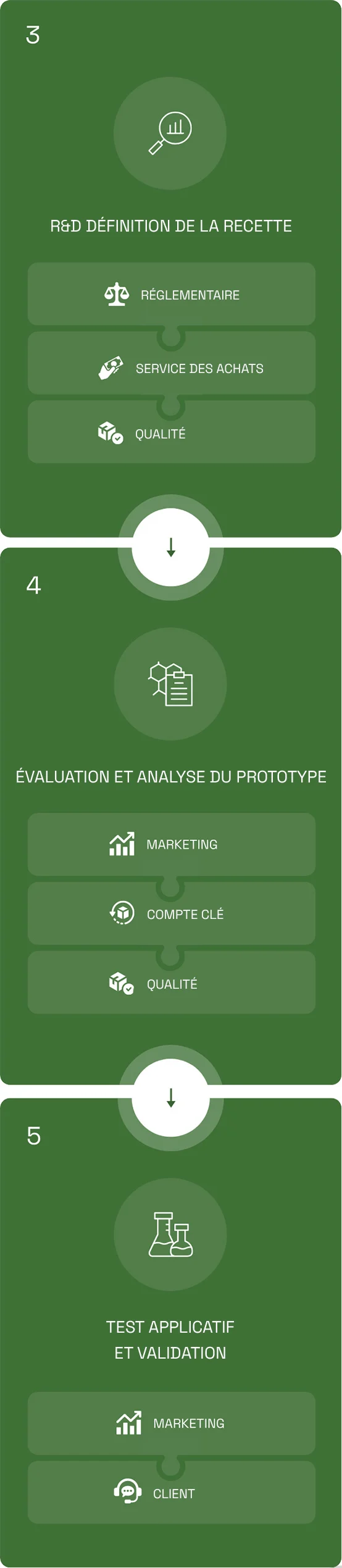

The heart of our method is the product development R&D process.

Definition request

Ours is a tailor-made approach, developed to meet the needs of partners active in the food industry.

Thanks to the field experience and the ability to internally test the product, we can create and provide our customers with high-quality, customized recipes, differentiated by application and process type, meeting customer needs in terms of flexibility, speed, and efficiency.

Our professionalism is enhanced by continuous market research and ensured by the valuable exchange of information with the sales network. Our strength is reliability, ensured by unceasing cooperation with the Quality Assurance and Control, Production, Management Control and Technical Departments, which enables us to assess the feasibility of the request and if not, to propose alternative solutions that can satisfy it.

The ability to understand and embrace customer needs is made possible by constant communication and cooperation between our R&D department and our customers’ R&D function.

Recipe definition

The professionalism and preparation of our R&D function is a high added value to our clients’ business through the implementation of ad hoc solutions structured on 3 main phases:

« We make a difference by combining protocols that act as quality assurance with a high level of customization, which ensures that there is a wide range of formulations. »

Definition of the recipe

Pilot product realization

Application testing

Definition of the recipe

Based on the customer’s specific requirements, a recipe that satisfies in terms of organoleptic characteristics and performance is defined, starting from an established know-how of formulation and knowledge of raw materials and preliminary laboratory tests.

Pilot product realization

Our R&D is equipped with a plurality of pilot plants, enabling testing of various applications of the proposed solutions. The prototype traces the basic characteristics of the industrial product and is characterized in-house:

-Chemical-physical analyses: Unigrà’s in-house laboratory is equipped with numerous tools for characterizing products and verifying that they meet the parameters identified to arrive at the desired target.

–Panel test: gli assaggi permettono di operare confronti con un riferimento o stabilire una preferenza tra più campioni prodotti, andando a selezionare il prototipo idoneo alla campionatura

Application testing

The prototype is tested at the Unigrà application laboratory, where pastry technicians test the product in the applications of interest, evaluating performance and organoleptic appearance in the product in which it is used. When the prototype is deemed to be in line with the requirements, it is sent to the customer so that they can evaluate it directly and give feedback on which to continue product development.

These steps are monitored by cross-sectional control methods. These controls are used to ensure chemical-physical, microbiological and organoleptic compliance, but most importantly on application performance.

Definition of the recipe

Definition of the recipe

Based on the customer’s specific requirements, a recipe that satisfies in terms of organoleptic characteristics and performance is defined, starting from an established know-how of formulation and knowledge of raw materials and preliminary laboratory tests.

Pilot product realization

Pilot product realization

Our R&D is equipped with a plurality of pilot plants, enabling testing of various applications of the proposed solutions. The prototype traces the basic characteristics of the industrial product and is characterized in-house:

-Chemical-physical analyses: Unigrà’s in-house laboratory is equipped with numerous tools for characterizing products and verifying that they meet the parameters identified to arrive at the desired target.

–Panel test: gli assaggi permettono di operare confronti con un riferimento o stabilire una preferenza tra più campioni prodotti, andando a selezionare il prototipo idoneo alla campionatura

Application testing

Application testing

The prototype is tested at the Unigrà application laboratory, where pastry technicians test the product in the applications of interest, evaluating performance and organoleptic appearance in the product in which it is used. When the prototype is deemed to be in line with the requirements, it is sent to the customer so that they can evaluate it directly and give feedback on which to continue product development.

These steps are monitored by cross-sectional control methods. These controls are used to ensure chemical-physical, microbiological and organoleptic compliance, but most importantly on application performance.

Industrialization

The last stage of new product development is industrialization.

The recipe and parameters used at the pilot must be brought to industrial scale. Fundamental is the coordination between all business functions involved: research and development, together with quality assurance, supports production at this stage, so that the recipe and operating conditions are adjusted such that the product meets the specifications established at the prototyping stage.

Initial industrialization trials are then sent to and tested by the customer until final product approval.

The high level of production quality is guaranteed right down to the sourcing of raw materials: even for these, before being used in production, there is a protocol of not only application but also documentary approval, choosing suppliers in line with Unigrà’s quality standards, including religious and sustainability certifications.

Our decades of experience in the field of oils and greases combined with a plurality of applications that we carry out in-house through the production of related products enables us to test in-house, produce, use and offer customers the best solutions.

Initial industrialization trials are then sent to and tested by the customer until final product approval.

The high level of production quality is guaranteed right down to the sourcing of raw materials: even for these, before being used in production, there is a protocol of not only application but also documentary approval, choosing suppliers in line with Unigrà’s quality standards, including religious and sustainability certifications.

Our decades of experience in the field of oils and greases combined with a plurality of applications that we carry out in-house through the production of related products enables us to test in-house, produce, use and offer customers the best solutions.

Our main control systems

Microbiological Controls

Raw materials, semi-finished and finished products are analyzed to proceed to release for use.

Chemical-physical controls

Characterization of raw materials and products ensures their compliance with set parameters and lastandardization of productions.

Such controls make it possible to ensure product performance. Examples of the tools available include:

– NMR:per la misurazione del contenuto dei solidi sulla fase grassa, un importante indicazione sul suo comportamento nelle diverse applicazioni.

– REOMETRO: controllo delle proprietà reologiche di creme e surrogati, per determinarne le principali caratteristiche utili per il processo incui verranno usati e per la sua performance in applicazione.

Contaminant controls

Unigrà verifies the compliance of products from the point of view of contaminants, comparing methods and instruments with leading analysis laboratories of reference both nationally and internationally, thus ensuring the reliability of the result and the speed of an internal control.

These include, for example, 3-MCPD and GE, two process contaminants formed during the refining of oils. Unigrà has a monitoring plan that allows within a day to have the result on these contaminants and total control over all critical processes.

Controls on organoleptics

There is a group of trained panelists on the various product categories from oil to vegetable beverages who evaluate according to standard tasting sheets the organoleptics of the product, and if necessary of the raw materials used. These panels also serve as support in defining the shel life of the product itself.

Application controls

Unigrà’s application laboratory has equipment for pastry, bakery, and ice cream preparations in order to test different productions with appropriate controls and provide support during the development stages of a new product, with tests aimed at verifying application performance.