The key ingredient for your business success.

We make top-class agri-food raw materials, semifinished and finished products for businesses, artisans, retail and HoReCa industries. Because success is all about the ingredients.

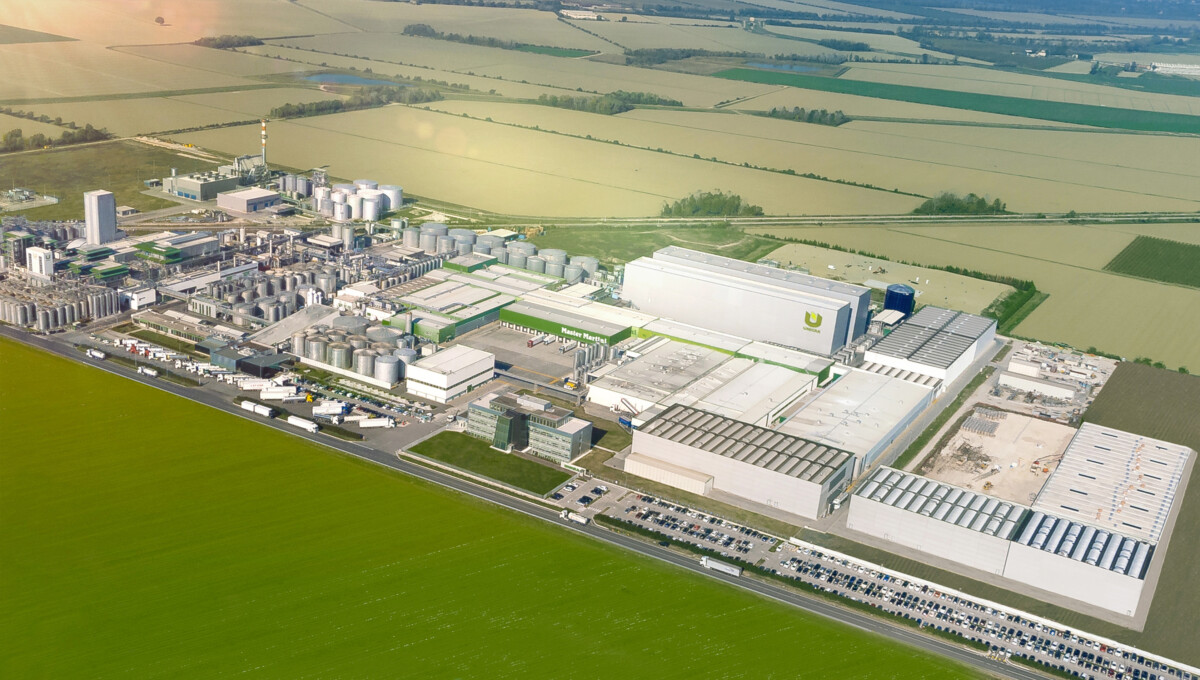

Your business success starts here, where all the ingredients are picked and processed with cutting-edge technologies.

The best masters and the finest ingredients will lead your business to success. Unica is the Unigrà training school that supports professionals to achieve the highest degree of specialisation in pastry, bakery, chocolate, gelato and cooking.